The F/A-18A-D APG-65/73 Radar Transmitter is supported on Consolidated Automated Support System (CASS); however, the fleet was experiencing a high call-out and removal rate of the Transmitter 1A2 HVPS subassembly with a 75% no-fault-found (A799) rate for the 1A2 HVPS reported back from the next higher level of maintenance. In an effort to reduce the high Aviation Depot Level Repairable (AVDLR) expenditures for fleet Beyond Capability of Maintenance (BCM) actions of the 1A2 HVPS used in both the APG-65 and APG-73, PIDESO developed and fielded a standalone 1A2 HVPS Test Set.

As a COMFRC-Aviation Readiness Action Team (ARAT) sponsored project, PIDESO re-engineered and developed a specialized test and check capability for the 1A2 HVPS subassembly. After an initial prototype demonstration, PIDESO engineers perfected the design and demonstrated capability to extend beyond test and check to full ready for issue (RFI). The added capability also enabled depot artisans to isolate faulty subcomponents on the 1A2 HVPS and facilitate repairs. The 1A2 HVPS test cart currently used by embedded depot-level artisans has extended capability at targeted maintenance facilities.

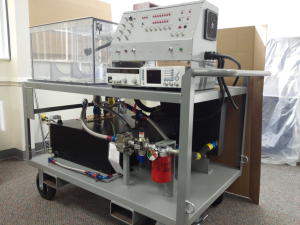

The mobile HVPS tester provides the stimulus for the HVPS and measures the electrical output voltage while the 1A2 HVPS is submerged in Polyalphaolefin (PAO) dielectric lubricant necessary for cooling. The test system includes test equipment necessary to verify electrical response and signal timing at breakout test points on the 1A2 HVPS that are electrically interfaced with the test cart control panel. When the 1A2 HVPS is under test the test cart uses a pump, a drain, and diverter valves that are adjustable to allow the pump to continue recirculating the PAO through the test cart heat exchanger to keep the HVPS cool during operation. The HVPS is stepped through a testing procedure developed by PIDESO and approved by the Radar Government Team. The procedure guides the artisan through test measurements leading to identification of a failed sub-component or to full RFI.

The mobile HVPS tester provides the stimulus for the HVPS and measures the electrical output voltage while the 1A2 HVPS is submerged in Polyalphaolefin (PAO) dielectric lubricant necessary for cooling. The test system includes test equipment necessary to verify electrical response and signal timing at breakout test points on the 1A2 HVPS that are electrically interfaced with the test cart control panel. When the 1A2 HVPS is under test the test cart uses a pump, a drain, and diverter valves that are adjustable to allow the pump to continue recirculating the PAO through the test cart heat exchanger to keep the HVPS cool during operation. The HVPS is stepped through a testing procedure developed by PIDESO and approved by the Radar Government Team. The procedure guides the artisan through test measurements leading to identification of a failed sub-component or to full RFI.

Production 1A2 HVPS testers have been provided to FRC-West (NAS Lemoore) and to FRC-Mid Atlantic (NAS Oceana) and are contributing to monthly cost-avoidance goals at each site. Additional production testers are under development and planned for USMC MALS deployment. The testers are designated for depot artisan use at the Level-2 support activities and are supported under the COMFRC BCM-Interdiction Reduced Total Ownership Costs (RTOC) initiative. Avoiding unnecessary cost for maintenance and increase RADAR readiness.